Basalt Fiber Board

PRODUCT INTRODUCTION

Basalt fiber board can be divided into two categories: solid board and sandwich panel.

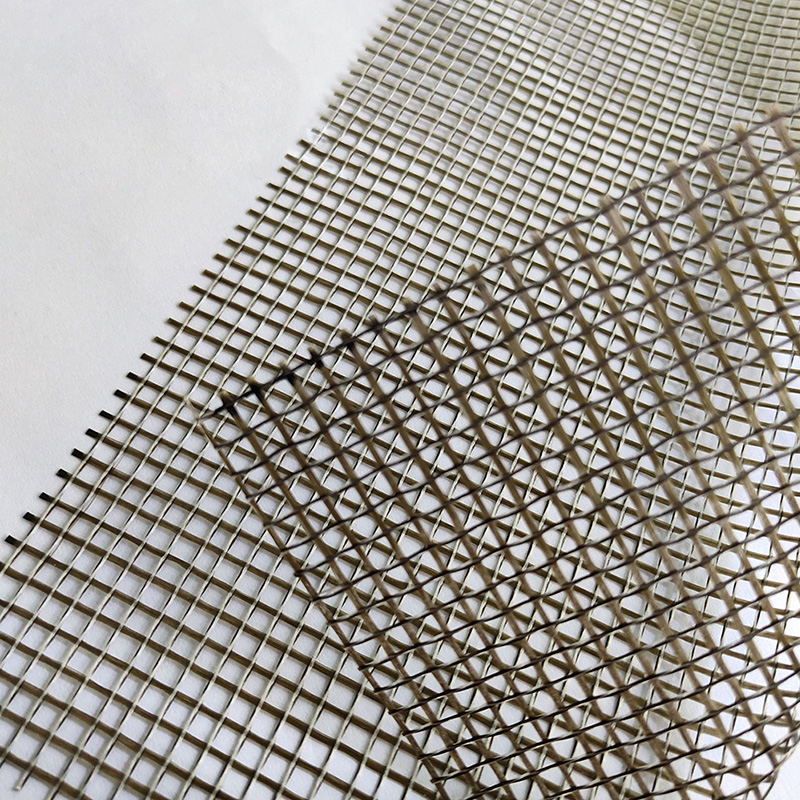

Solid panels are made of continuous basalt fibers through short cutting, carding, needling to form a three-dimensional interlaced structure of basalt fiber needle felt, mixed with a small amount of binder made of high temperature and high pressure.

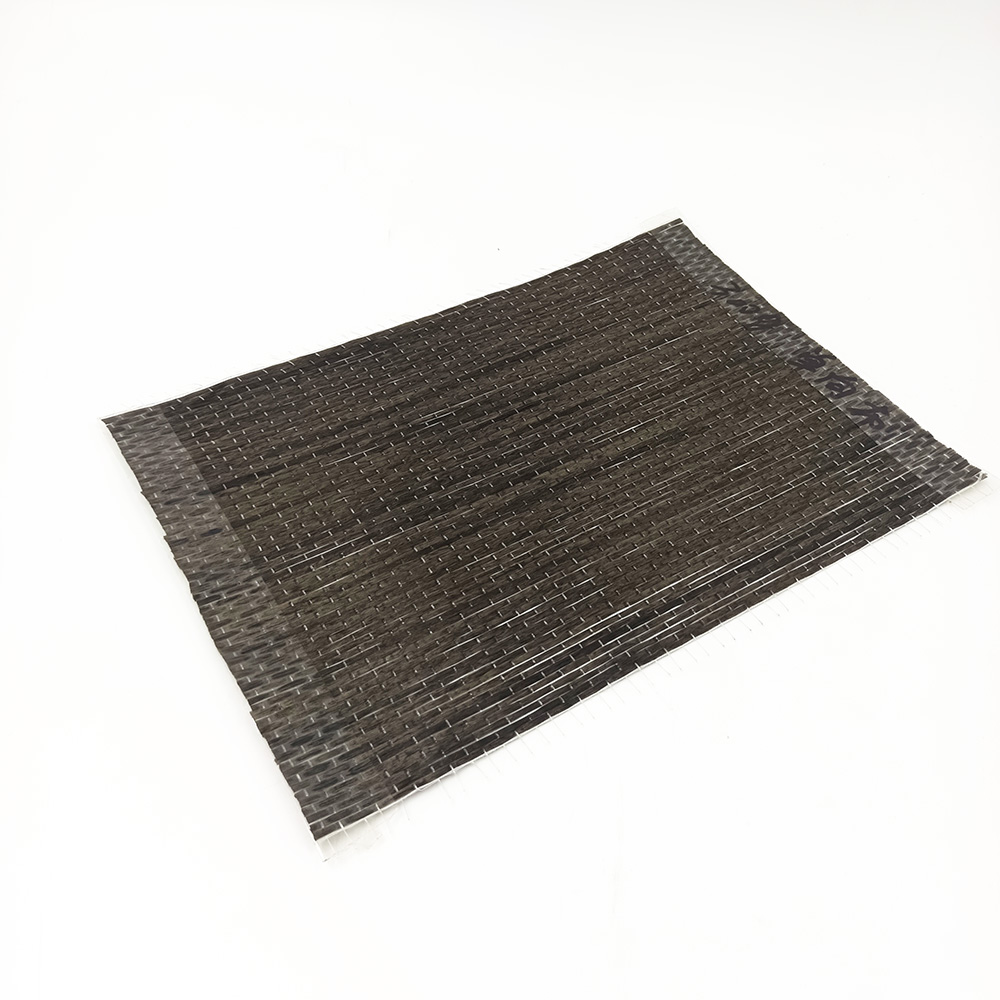

Sandwich panel is a thin solid board for the upper and lower panels, spliced rock wool strips as the core material, bonded by high temperature and pressure into a sandwich structure.

PRODUCT FEATURES

Excellent fire resistance, excellent mechanical properties, environmental health, long-lasting weather resistance, heat insulation and energy saving, sound-absorbing anti-magnetic, anti-corrosion insulation and other advantages.

PRODUCT SPECIFICATION

|

Performances |

Basalt Fiber Board |

|

|

|

Solid Board |

Sandwich Panel |

|

Tensile Strength (Kpa) |

≥12 |

≥12 |

|

Thermal Conductivity (W/(m.K) 25℃) |

≤0.036 |

≤0.040 |

|

Density (kg/m3) |

≥160 |

≥150 |

|

Compressive Strength (kg/m2) |

≥380 |

≥125 |

APPLICATIONS

External insulation of building walls (thin plaster mortar system and decorative integrated system); panels for internal wall ceilings, partitions and sound-absorbing panels..