News

A New Era of Innovation: Basalt Fiber Mat Leading Application Advancements

As global demand for high-performance, eco-friendly materials continues to surge, Basalt Fiber, a novel inorganic fiber material derived from volcanic rock, is demonstrating vast application potential due to its exceptional properties. Today, Beihai Composites officially announces its commitment to driving the innovative application of basalt fiber felt across multiple key sectors, providing customers with safer, more efficient, and sustainable solutions.

Breakthroughs and Growth Mark New Era for Basalt Fiber Industry

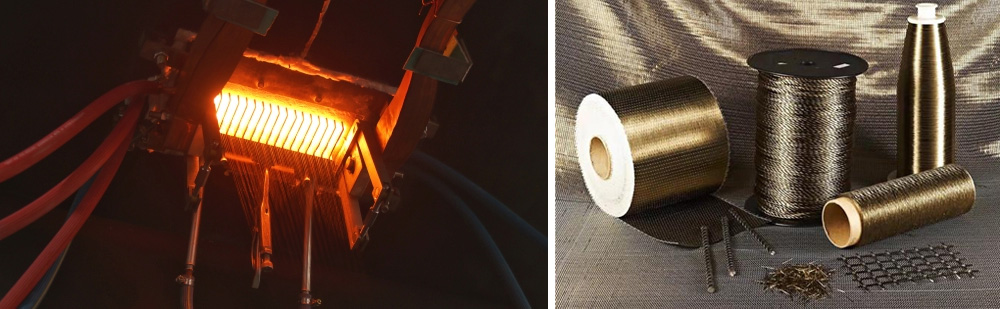

In a significant stride for the materials sector, the basalt fiber industry is witnessing a wave of advancements and expansion. Recently, on April 14th, Xinjiang Tuoxin Basalt Industry Co., Ltd. successfully produced its first batch of basalt fibers after a technological upgrade. This revival, following a hiatus since 2016, was achieved through a “lease + technological transformation” model led by the Alar Economic and Technological Development Zone, with the introduction of CEEC (Xinjiang) New Materials Co., Ltd. The upgrade, which involved doubling the number of holes in the drawing equipment to 400 and adopting a dual - design, has significantly enhanced the annual production capacity to 1,200 tons.

300Tex Basalt fiber twisted yarn Ship to USA

Product: Basalt fiber twisted yarn

Usage: Weaving

Loading time: 2024/12/6

Loading quantity: 60KGS)

Ship to: USA

Specification:

Material: Basalt Fiber

Linear Density: 300tex

Filament Diameter: 13 microns

Twist: Z50

Economic and environmental advantages of basalt fibers in concrete reinforcement

Basalt fiber is a versatile and sustainable material that is becoming increasingly popular in the construction industry as a reinforcement for concrete. With its economic and environmental advantages, basalt fiber is revolutionizing the way we approach concrete reinforcement, providing a cost-effective and environmentally friendly alternative to traditional materials. In this blog, we will explore the benefits of basalt fiber in concrete reinforcement and its potential to change the construction landscape.

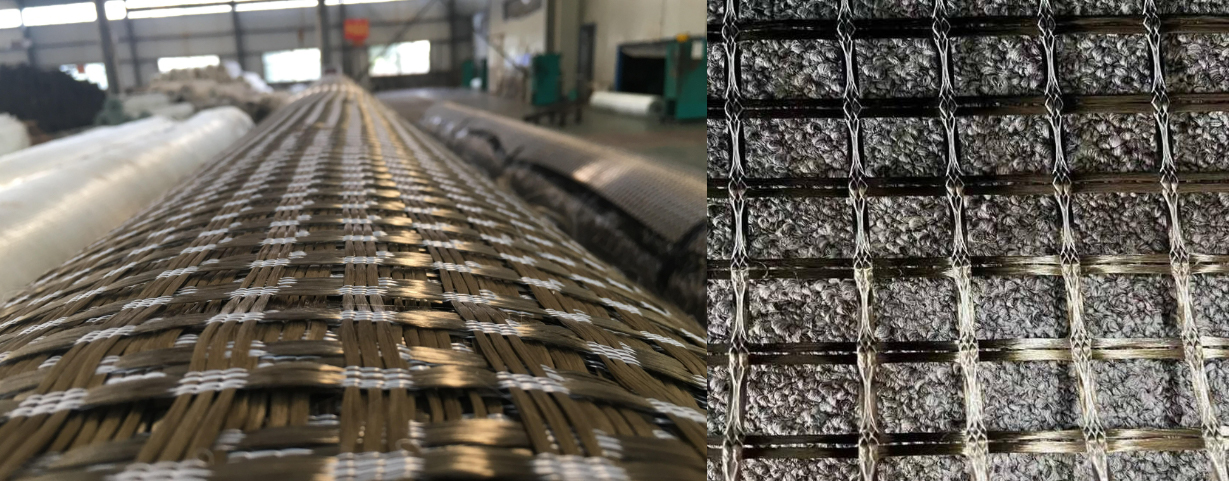

Basalt fiber winding reinforced PE pipe production process

Basalt fiber reinforced PE composite pipe, the use of basalt fiber left and right spiral winding molded mesh skeleton as a reinforcing body, high-density polyethylene (HDPE) as a substrate, and high-performance adhesive resin layer will be basalt fiber skeleton, and the inner and outer layers of high-density polyethylene tightly connected, mixing screw extruder production line continuous molding of the new type of double-sided anticorrosive pressure pipeline.

What kind of rock is basalt?

Basalt is a basaltic ejecta, a rock with a dense or foamy structure formed by the cooling of magma from volcanic eruptions at the surface, and is a magmatic rock. It is also a major constituent of the Earth's oceanic crust and the Moon's lunar sea (note: the lunar sea is the low-lying plain on the lunar surface where dark-colored minerals are observed on the Moon).

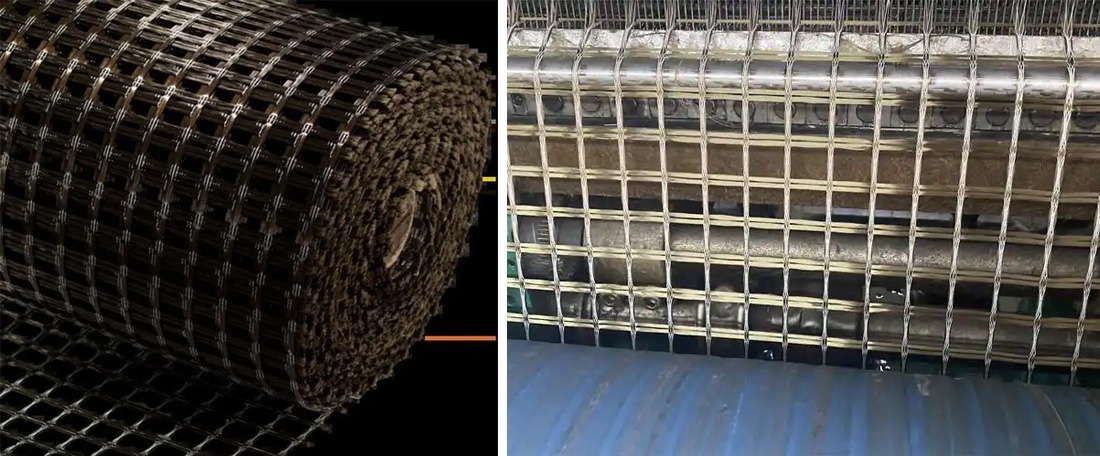

Flame Retardant Basalt Grating for Underground Coal Mines

Flame retardant basalt grating for underground coal mine is a kind of grating material specially designed for underground coal mine support works. It has the characteristics of flame retardant and anti-static, which can effectively improve the safety coefficient of coal mine underground.

Mechanical Properties of Basalt Fiber chopped strands Concrete

Concrete, as a widely used Building Material in civil engineering, has good mechanical properties, but with the continuous deepening of the application of engineering technology, the shortcomings of its basic mechanical properties are gradually exposed. Due to the low tensile strength characteristics of only one-tenth of the compressive strength, resulting in members of the tensile process is prone to cracking, which directly reduces the durability of the components, narrowing the scope of application of concrete materials.

Basalt fiber flame kiln consumes high energy, how to save energy

At present, there are many enterprises doing research work on the large-scale production of basalt fiber, but there are still certain technical problems in production, such as the high capacity of the related units, low production efficiency, and other issues. Basalt fiber pool kiln production is a systematic project, that must continue to study and improve the corresponding supporting equipment, to solve each link to sustain development.

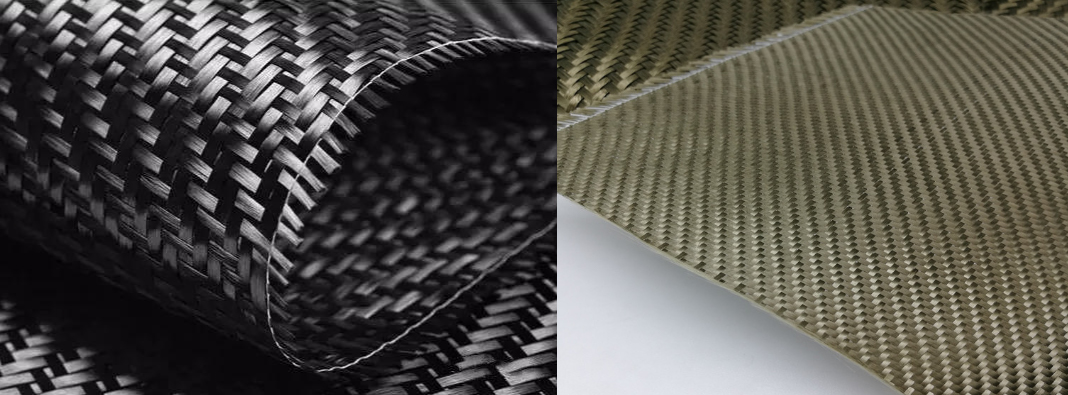

Basalt fiber belongs to what material

Basalt continuous fiber is a kind of pure natural inorganic non-metallic material, which is the new material of the 21st century and one of the most important components of the new material industry. Basalt fiber is similar to glass fiber, its performance is between high strength S glass fiber and alkali-free E glass fiber, is a pure natural high-tech fiber, because the fiber color is golden brown, also known as “golden fiber”.